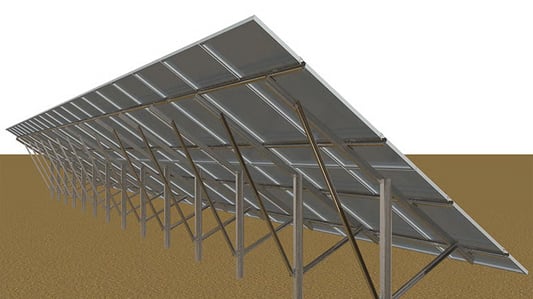

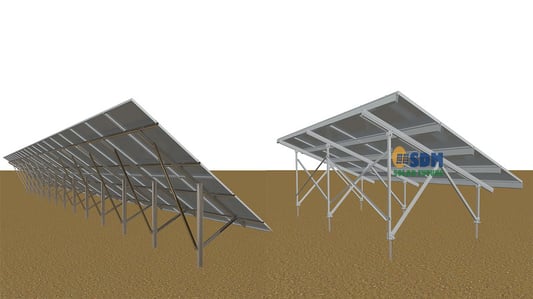

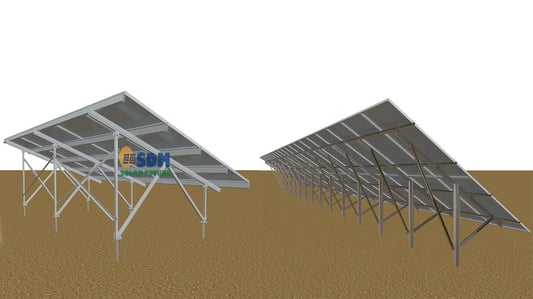

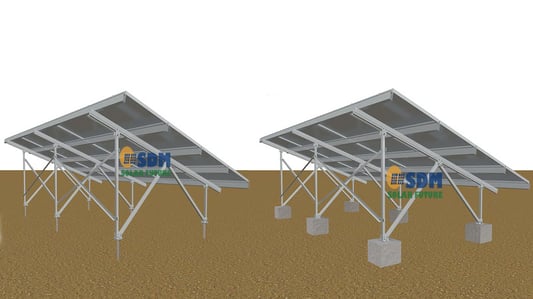

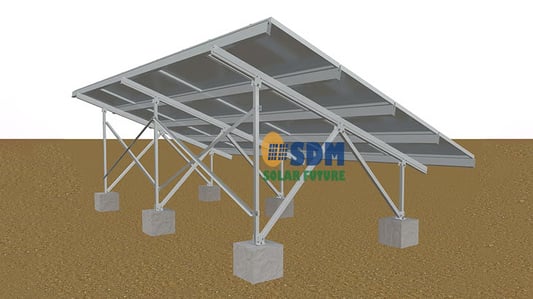

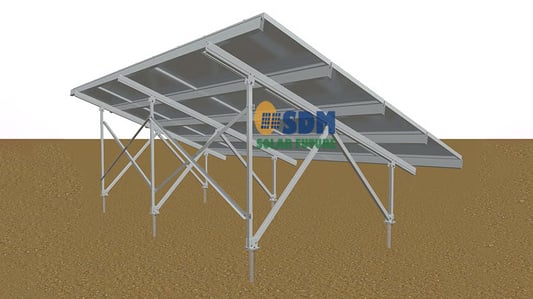

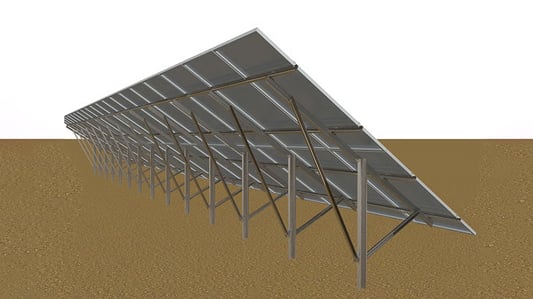

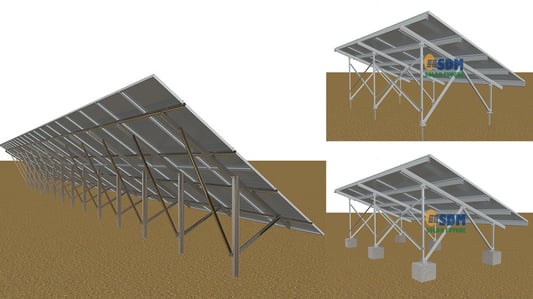

Understanding ZAM SteelZAM steel, also known as Zinc, Aluminum, and Magnesium coated steel, is gaining popularity in the industry for its exceptional corrosion resistance properties. This innovative material is designed to withstand harsh environmental conditions, making it an ideal choice for ground mounting systems.Corrosion Prevention MechanismsThe Corrosion resistance of ZAM steel in ground mounting systems is primarily attributed to its unique composition. The combination of zinc, aluminum, and magnesium creates a protective barrier that prevents the steel from coming into contact with moisture and other corrosive elements in the environment.Longevity and DurabilityOne of the key advantages of using ZAM steel in ground mounting systems is its unparalleled longevity and durability. This material has a longer lifespan compared to traditional steel, making it a cost-effective investment for solar panel installations.Environmental SustainabilityIn addition to its superior corrosion resistance properties, ZAM steel is also known for its environmental sustainability. The use of this material in ground mounting systems helps reduce the carbon footprint of solar energy production, making it a more eco-friendly option for renewable energy projects.Cost-EfficiencyWhile ZAM steel may have a higher upfront cost compared to traditional steel, its long-term benefits far outweigh the initial investment. The corrosion resistance of ZAM steel in ground mounting systems helps reduce maintenance costs and extends the lifespan of the entire system.Installation FlexibilityAnother advantage of using ZAM steel in ground mounting systems is its installation flexibility. This versatile material can be easily customized to fit various solar panel configurations, making it a popular choice among installers and project developers.Performance in Harsh EnvironmentsGround mounting systems are often exposed to extreme weather conditions, making corrosion resistance a critical factor in their performance. ZAM steel has been proven to withstand the harshest environmental elements, ensuring the structural integrity of the entire system.Comparative AnalysisWhen comparing the corrosion resistance of ZAM steel to other materials commonly used in ground mounting systems, such as galvanized steel or aluminum, ZAM steel consistently outperforms in terms of longevity, durability, and overall performance.Maintenance ConsiderationsWhile ZAM steel is known for its low maintenance requirements, routine inspections and upkeep are still necessary to ensure optimal performance. Regular cleaning and inspection of the ground mounting system can help identify any potential issues early on and extend the lifespan of the structure.Future OutlookAs the demand for renewable energy continues to grow, the importance of corrosion resistance in ground mounting systems will only increase. ZAM steel is poised to play a pivotal role in the development of sustainable energy infrastructure, offering a reliable and durable solution for solar panel installations.Quote Inquirycontact us